-

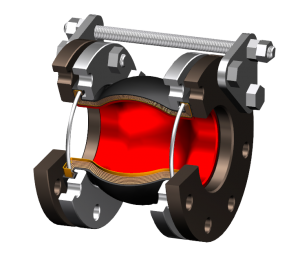

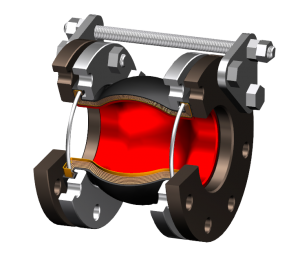

A-1 ~Single Arch Rubber Expansion Joint

The single-arch product can reduce the vibration and noise, which can also solve the axial/lateral/angular movements/eccentric problems. Reinforcement layer of the bellows by Nylon cords and at both ends by hardened steel wire rings. The floating steel flanges are drilled according to DIN, ANSI, BS, JIS and other standards. If the piping pressure is much higher, reinforced bolts should be assembled together with flanges. -

PTFE Lined rubber expansion joints

The rubber expansion Joint with PTFE provide good corrosion-resistance and good chemical -resistance in piping system. The PTFE are lined through the entire length of the joint and covers both end flanges completely. The PTFE liner is backed by a fabricated rubber body, the reinforced middle layer is impregnated with nylon tire cords, which can increase the flexibility and stiffness. The outer cover is used according tot the working conditions, such as UV resistance, acid-resistance, or alkal... -

Abrasion resistance rubber expansion joints

Expansion rubber joints are assembled on the piping, which can reduce the vibration, reduce noise, protect pipe system from start-up forces as well as system surges, compensate movements and misalignments from the piping line. The rubber joints are used below systems, but not limited Commercial HVAC systems Industrial piping systems Power plants Sewage treatment plants The material of tube is reinforced natural rubber, which can increase the abrasion resistance, worn-resistance. This rubber m... -

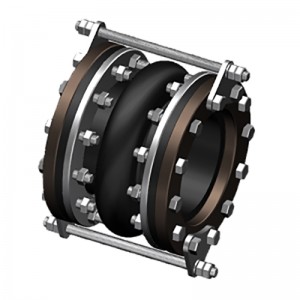

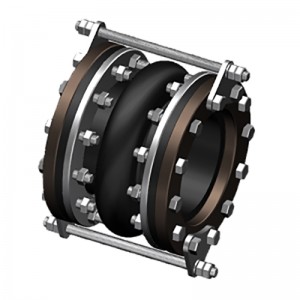

A-2 ~Double Arch Rubber Expansion Joint

Double-arch products are used where more movement is needed. If the piping pressure is much higher, reinforced bolts should be assembled together with flanges. Reinforcement layer of the bellows by Nylon cords and at both ends by hardened steel wire rings. The floating steel flanges are drilled according to DIN, ANSI, BS, JIS and other standards. -

A-5 ~Threaded Union

Threaded unions is used When an economical threaded pipe connection is needed, the surface of the union is available both hot-dip galvanizing and electroplating. Both ends provided with a malleable iron union with female thread BS or ANSI. -

A-9 ~Other Products

Rubber gasket has oil resistance, acid and alkali resistance, cold and heat resistance, aging resistance and other properties. Based on different using purpose, the material of rubber gasket is different. We can make gaskets in EPDM,Buna, natural rubber. If special material requirement, we can meet the requirements. -

A-8 ~Standard Flanges

The elastomers are assembled with the mating flanges, with different standards and different pressures. Sometimes, buyers need us to buy for them, shipped together with rubber joints. -

A-7 ~Rubber Pipe Connector

Rubber Pipe is an economical, abrasion-resistant replacement for steel and cast iron pipe, either in straight lengths or where a specified radius is required. B-1 Rubber Pipe may be used in conveying ore, corrosive chemicals, sand,and other abrasive slurries. -

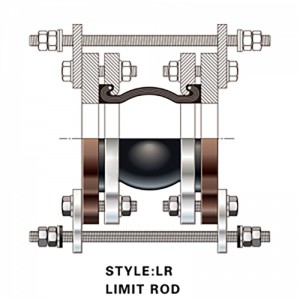

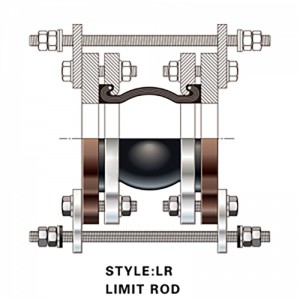

A-6 ~Control Units

A control unit assembly is a system of two or more control rods placed across an expansion joint from flange to flange to minimize possible damage to the expansion joint caused by excessive motion of the pipeline. The control rod assemblies are set at the maximum allowable expansion and/or contraction of the joint and will absorb the static pressure thrust developed at the expansion joint. When used in this manner, they are an additional safety factor, minimizing possible failure of the expansion joint and possible damage to the equipment. Control units will adequately protect the joints, but the user should be sure that the pipe flange strength is sufficient to withstand total force that will be encountered. -

A-4 ~Spool Type Rubber Expansion Joint

The spool type rubber joint is molded type, with a metal collar reinforced at the neck of the body. The ST stype uses a light reaining ring to support the integral flange. STF is filled arch, with 50% of the ST allowed movements, but it has 4 times spring rates than hollow arch. -

A-3 ~Wide Arch Rubber Expansion Joint

Wide arch system is the molded expansion joint, with integral flange and without a metal reinforcement at the neck of the body. Wide arch allows greater movements and low spring rates comparing to spool type. WA and WAF is used for an economical wide arch rubber expansion joint. WAF is filled arch, with 50% of the WA allowed movements, but it has 4 times spring rates than wide arch.